Technological innovation on conveyor belts splicing with high duration.

Splice taken to the next level!

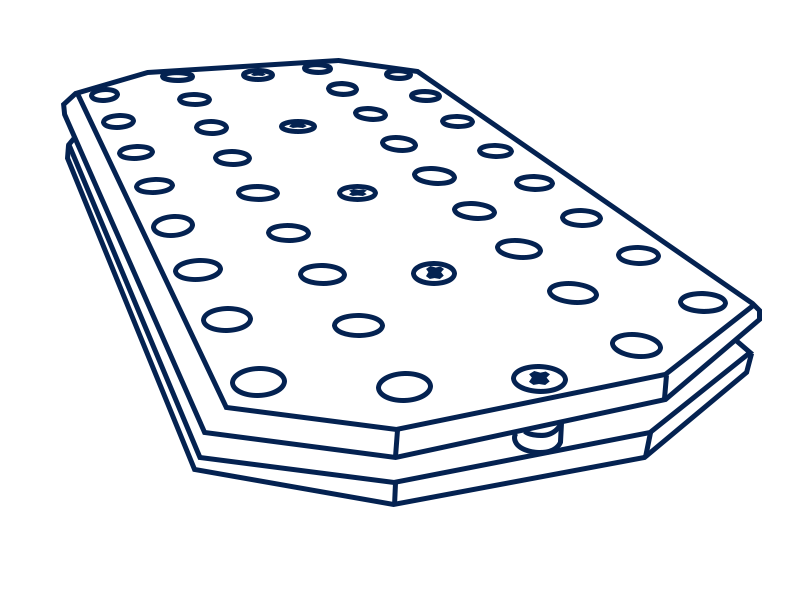

The Raptor In-Splice system made up of two high-resistance rubber parts with reinforced metal and textile inserts and joined by self-tapping screws is your best option for joints in textile conveyor belts due to its resistance, quick installation and reliability.

Raptor In-Splice system technology improves splice performance and saves downtime costs of a conventional vulcanized splice.

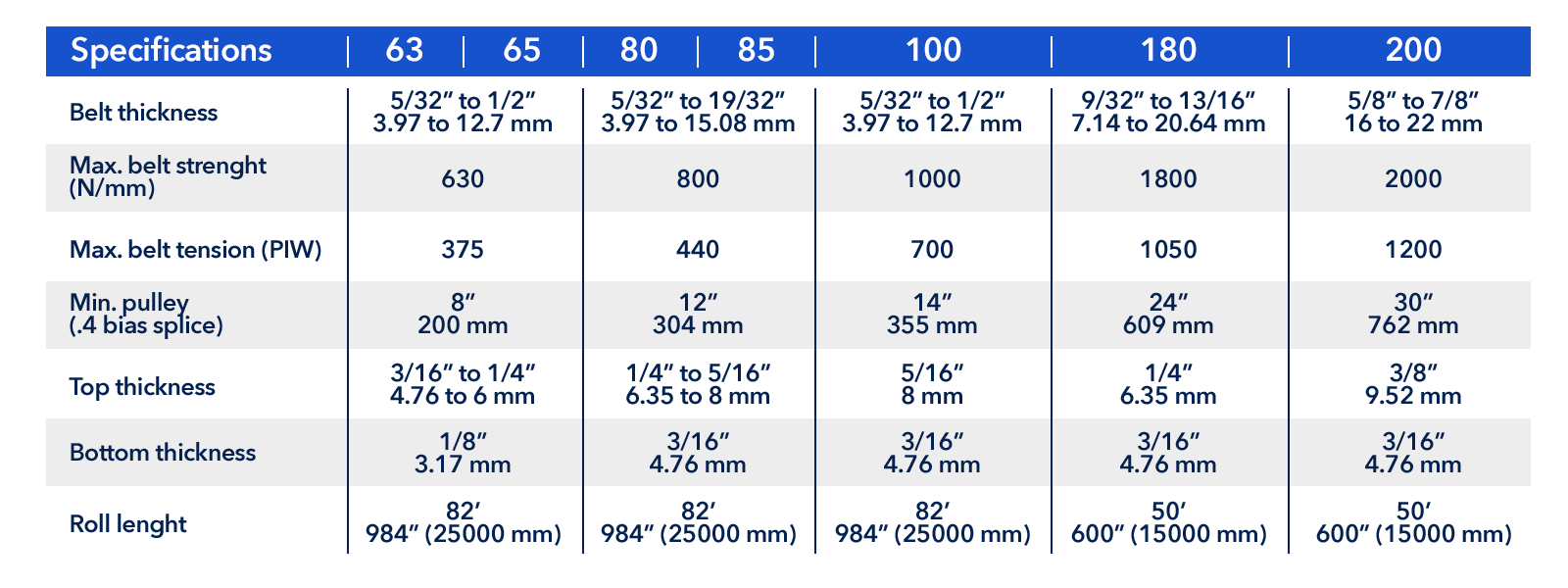

Installation capacity in belts of any width and tension ranging from 200 PIW to 1200 PIW.

Built with the

Highest Quality

Available in five different compounds depending on which suits your processes the most.

- Easy & fast installation.

- Cost reduction in installation.

- Suitable for any climatic condition.

- Excellent for tear or gouge repairs due to it’s longitudinal installation capability.

- Great flexibility for use on small diameter pulleys.

- No preparation or drilling templates required.

- Compatible with scrapers and cleaning systems.

- Prevents loss of material by filtration.

- Cut, abrasion and tension resistant.

Industries

Mining in general, coal, cement, aggregates, sand, grain, sawmills, foundry, chemical processes, recycling and industry in general.

Photo Gallery